A failing clutch master cylinder directly impacts your truck’s performance. It compromises both drivability and safety on the road. This guide provides you with data-backed strategies. You can effectively diagnose and resolve these critical issues. This ensures your vehicle operates reliably.

Key Takeaways

- A working clutch master cylinder is important for your truck. It helps you shift gears smoothly. It keeps your truck safe to drive.

- Watch for signs of a bad clutch master cylinder. These include a soft pedal, hard shifting, or fluid leaks. Fixing problems early saves money.

- You can make your clutch master cylinder last longer. Check fluid often. Replace old fluid. Fix any leaks quickly.

Understanding the Truck Clutch Master Cylinder

How the Clutch Master Cylinder Operates in a Hydraulic System

The Clutch Master Cylinder acts as the heart of your truck’s hydraulic clutch system. When you press the clutch pedal, you push a piston inside this cylinder. This action forces hydraulic fluid through a line. The fluid then travels to the slave cylinder. The slave cylinder receives this pressure. It then moves the clutch release fork. This movement disengages the clutch from the flywheel. Releasing the pedal allows the fluid to return. This re-engages the clutch. This hydraulic process ensures smooth and efficient power transfer from your engine to the transmission.

Why a Functional Clutch Master Cylinder is Essential for Truck Performance

A properly working clutch master cylinder is crucial for your truck’s performance. It allows you to shift gears smoothly and precisely. Without it, you experience difficulty changing gears. This can lead to grinding or missed shifts. A functional master cylinder also prevents premature wear on other clutch components. It ensures the clutch engages and disengages fully. This protects your transmission and engine from unnecessary strain. You maintain optimal control over your vehicle. This directly impacts both safety and operational efficiency.

Recognizing Common Symptoms of a Failing Clutch Master Cylinder

You need to recognize the signs of a failing clutch master cylinder early. This helps you prevent bigger problems. Pay attention to how your truck’s clutch feels and acts.

Identifying a Spongy or Soft Clutch Pedal

You press the clutch pedal. It feels unusually soft or spongy. This is a common symptom. It often means air has entered your hydraulic system. Air compresses, unlike fluid. This makes the pedal feel less firm. Internal seal failure within the Clutch Master Cylinder can also cause this feeling. The seals do not hold pressure correctly. This reduces the hydraulic force needed for proper clutch operation.

Diagnosing Difficulty Shifting Gears Related to the Clutch Master Cylinder

You experience trouble shifting gears. You might hear grinding noises when you try to engage a gear. Or, you find it hard to get into gear at all. This happens because the clutch does not fully disengage. A faulty clutch master cylinder cannot generate enough pressure. This prevents the clutch from separating completely from the flywheel. You need a fully disengaged clutch for smooth gear changes.

Visual Checks for Low or Contaminated Clutch Fluid

You should regularly check your clutch fluid reservoir. Look at the fluid level. Is it low? A low fluid level often points to a leak somewhere in the system. Also, inspect the fluid’s appearance. Is it dark, murky, or does it contain debris? Contaminated fluid reduces the system’s efficiency. It can also indicate internal wear within the master cylinder or other components. Clean, clear fluid is essential for proper function.

Addressing a Clutch Pedal Sticking to the Floor

Your clutch pedal stays on the floor after you press it. This is a clear and serious sign of a problem. Internal seal failure within the clutch master cylinder usually causes this. The seals fail to return the fluid to its original position. This leaves the pedal depressed. You cannot operate your truck safely with a pedal that sticks.

Pinpointing Fluid Leaks from the Clutch Master Cylinder

You might notice fluid leaks. Check around the clutch master cylinder itself. Look for wet spots or drips on the firewall behind the pedal. You might also see fluid on the floor under your truck. These leaks mean you are losing hydraulic pressure. A loss of pressure directly impacts the clutch’s ability to engage and disengage. Address any fluid leaks immediately to prevent complete system failure.

Data-Backed Diagnosis of Clutch Master Cylinder Problems

You need a clear, systematic approach to pinpoint clutch problems. This helps you avoid unnecessary repairs. You can accurately identify if your Clutch Master Cylinder is the source of trouble.

Step-by-Step Diagnostic Process for the Clutch Master Cylinder

Follow these steps to diagnose your clutch system effectively:

- Inspect the Clutch Fluid Reservoir:

- Check the fluid level. Is it at the “Full” mark? A low level often indicates a leak.

- Examine the fluid color and clarity. Clean fluid is clear or slightly amber. Dark, murky, or contaminated fluid suggests internal wear or a need for replacement.

- Look for debris in the fluid. This can point to failing internal seals.

- Perform a Visual Leak Inspection:

- Look around the clutch master cylinder itself. Check for fluid stains or drips on the firewall inside the cab, near the pedal assembly.

- Trace the hydraulic line from the master cylinder to the slave cylinder. Look for any wet spots or signs of leakage along the line.

- Inspect the slave cylinder near the transmission. Leaks here can also cause similar symptoms, but the master cylinder might still be the primary issue if fluid is low.

- Test the Clutch Pedal Feel:

- Press the clutch pedal several times. Does it feel spongy, soft, or does it offer inconsistent resistance? This often means air is in the system or internal seals are failing.

- Note the pedal’s return. Does it return fully and quickly, or does it stick to the floor or return slowly? A sticking pedal strongly suggests a master cylinder problem.

- Listen for any unusual noises when you press or release the pedal.

- Check for Proper Clutch Engagement/Disengagement:

- With the engine running, try to shift into gear. Does it grind or resist? This indicates the clutch is not fully disengaging.

- If you can shift, does the clutch engage smoothly, or does it grab suddenly? A faulty master cylinder can affect engagement quality.

- Bleed the Clutch System (If Suspected Air):

- If you suspect air in the lines, bleed the system. Follow your truck’s service manual for the correct procedure.

- After bleeding, re-evaluate the pedal feel and shifting performance. If symptoms persist, the master cylinder likely has internal damage.

Distinguishing Clutch Master Cylinder Issues from Other Clutch Component Failures

You need to know the difference between a master cylinder problem and other clutch component failures. This saves you time and money.

- Master Cylinder vs. Slave Cylinder:

- Master Cylinder: You typically see fluid leaks near the pedal inside the cab. The pedal feels spongy or sticks to the floor. You have difficulty getting the clutch to disengage.

- Slave Cylinder: You usually find fluid leaks near the transmission. The clutch does not disengage fully, similar to a master cylinder issue. However, the pedal itself might feel normal until it loses all pressure.

- Tip: If the reservoir is low and you see leaks near the pedal, suspect the master cylinder. If leaks are only near the transmission, suspect the slave cylinder.

- Master Cylinder vs. Pressure Plate/Clutch Disc:

- Master Cylinder: The problem is hydraulic. The pedal feels wrong, or the clutch does not disengage. You do not typically experience clutch slipping.

- Pressure Plate/Clutch Disc: The clutch slips when you accelerate, especially under load. You might smell burning. The pedal usually feels normal, but the clutch does not transmit power effectively. You might also hear chattering or grinding noises when engaging the clutch.

- Master Cylinder vs. Release Bearing:

- Master Cylinder: Affects pedal feel and disengagement.

- Release Bearing: You hear a squealing or grinding noise when you press the clutch pedal. The noise usually goes away when you release the pedal. This is a mechanical noise, not a hydraulic issue.

Essential Tools and Equipment for Accurate Clutch Master Cylinder Diagnosis

You need the right tools to perform an accurate diagnosis. These tools help you confirm your suspicions.

- Flashlight: You use this for thorough visual inspections, especially in dark areas under the dash or around the transmission.

- Brake Fluid Tester: This tool measures the moisture content in your clutch fluid. High moisture content degrades fluid performance and can damage components.

- Hydraulic Pressure Gauge: You connect this to the clutch line. It measures the pressure the master cylinder generates. Low pressure confirms a faulty master cylinder.

- Shop Rags and Cleaner: You need these for cleaning up fluid spills and ensuring a clear view of potential leak points.

- Wrench Set and Socket Set: You use these to access and remove components for closer inspection or replacement.

- Clutch Bleeder Kit: This kit helps you remove air from the hydraulic system. It often includes a one-way valve or a vacuum pump.

Effective Solutions for Clutch Master Cylinder Repair and Replacement

You have diagnosed a problem with your truck’s clutch system. Now you need to decide on the best solution. This section guides you through repair, replacement, and maintenance.

Deciding Between Repairing or Replacing Your Clutch Master Cylinder

You face a choice: repair your existing unit or install a new one. Consider several factors.

- Cost: Repair kits are often cheaper than a full replacement. However, labor costs for repair can sometimes match replacement costs.

- Extent of Damage: If only a seal is worn, a repair kit might work. If the bore is scored or the housing is cracked, you need a new unit.

- Age and Wear: An older, high-mileage Clutch Master Cylinder might have other worn parts. A full replacement offers greater reliability.

- Time: Replacing the entire unit can sometimes be faster than disassembling, cleaning, and rebuilding an old one.

You should weigh these points carefully. A professional mechanic can help you make the best decision for your truck.

Choosing the Right Replacement Clutch Master Cylinder: OEM vs. Aftermarket

You decide to replace your clutch master cylinder. Now you must choose between OEM and aftermarket parts.

- OEM (Original Equipment Manufacturer): These parts come from your truck’s original maker. They guarantee a perfect fit and performance. They often cost more.

- Aftermarket: Other companies make these parts. They can offer good quality at a lower price. You need to choose a reputable brand.

Tip: Look for aftermarket brands with a strong reputation for quality and durability. FANGJIE, for example, offers the Truck Clutch Master Cylinder C40R13.1602290. This unit is engineered for heavy-duty applications. It provides reliable performance and comes in various specifications for wide compatibility.

You should always prioritize quality. A cheap, low-quality part can fail quickly. This leads to more repairs and downtime.

Overview of the Clutch Master Cylinder Replacement Process

Replacing your clutch master cylinder involves several key steps. You can understand the process even if you do not do the work yourself.

- Drain the Fluid: You first drain the old clutch fluid from the system.

- Disconnect Lines: You disconnect the hydraulic line and any electrical connections from the old master cylinder.

- Remove Old Unit: You unbolt the old master cylinder from the firewall.

- Install New Unit: You mount the new master cylinder in place. You reconnect all lines and connections.

- Refill Fluid: You fill the reservoir with fresh, correct-type clutch fluid.

- Bleed the System: You must remove all air from the hydraulic lines. This is a critical step.

You should always refer to your truck’s service manual for specific instructions. Each truck model can have unique requirements.

Proper Bleeding of the Clutch System After Master Cylinder Work

You must bleed the clutch system after any master cylinder work. Air in the lines causes a spongy pedal. It prevents proper clutch operation.

- Two-Person Method: One person pumps the clutch pedal. The other person opens and closes the bleeder valve on the slave cylinder. This pushes air out.

- Vacuum Bleeder: You can use a special tool to create a vacuum. This pulls fluid and air through the system.

- Pressure Bleeder: This tool applies pressure to the fluid reservoir. It forces fluid and air out through the bleeder valve.

You must continue bleeding until only clear, bubble-free fluid comes out. This ensures a firm pedal and full clutch engagement.

Preventative Maintenance to Extend Clutch Master Cylinder Lifespan

You can take steps to make your clutch master cylinder last longer. Preventative maintenance saves you money and trouble.

- Regular Fluid Checks: You should check your clutch fluid level often. Top it off if it is low.

- Fluid Flushes: You should flush and replace your clutch fluid periodically. Old fluid can become contaminated. It can absorb moisture. This degrades performance and harms internal components.

- Address Leaks Promptly: You should fix any fluid leaks as soon as you notice them. Even small leaks can lead to bigger problems.

- Use Correct Fluid: You must always use the type of hydraulic fluid specified by your truck’s manufacturer. Using the wrong fluid can damage seals.

You maintain your clutch system properly. This ensures smooth shifting and a long life for your components.

2025 Insights: Innovations in Clutch Master Cylinder Technology

You want to stay ahead in truck maintenance. Understanding the latest advancements in components helps you do this. Modern technology makes your truck’s clutch system more reliable and efficient.

Advanced Materials and Design Improvements in Clutch Master Cylinders

Manufacturers now use advanced materials. These include lighter composites and stronger plastics. They improve durability and reduce weight. You find better seal designs. These seals resist wear and fluid degradation more effectively. This extends the lifespan of the unit. Engineers also optimize internal bore finishes. This reduces friction and ensures smoother operation. These improvements mean fewer failures and less downtime for your truck.

The Impact of Electronic Systems on Clutch Master Cylinder Design

Electronic systems are changing how clutch components work. Sensors now integrate directly into the master cylinder. They provide precise data on pedal position and fluid pressure. This allows for more accurate clutch engagement. Electronic control units (ECUs) can interpret this data. They fine-tune clutch operation. This leads to smoother shifts and better fuel efficiency. You gain enhanced diagnostic capabilities. This helps you identify issues faster.

Future-Proofing Your Truck’s Clutch System with Modern Clutch Master Cylinders

You invest in modern components. This prepares your truck for future demands. Advanced designs and materials offer superior performance. They provide greater longevity. You reduce the need for frequent repairs. This saves you money and keeps your fleet operational. Choosing innovative parts ensures your truck’s clutch system remains reliable and efficient for years to come.

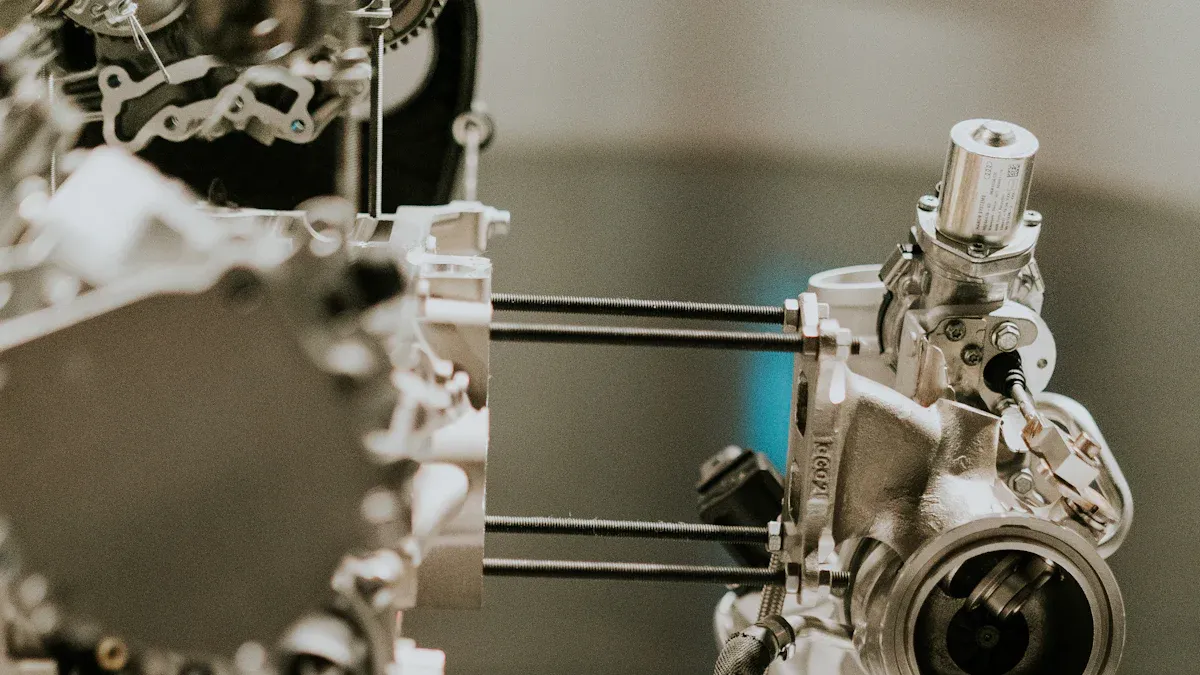

Introducing the FANGJIE Truck Clutch Master Cylinder C40R13.1602290

Consider the FANGJIE Truck Clutch Master Cylinder C40R13.1602290. Shaoxing Fangjie Auto Accessory Co., Ltd. engineers this critical component. It ensures seamless transmission operation. This unit boasts superior quality and robust construction. It withstands heavy-duty truck demands. You get exceptional durability and consistent performance. FANGJIE offers various specifications. These include different lengths, diameters, and thread types. This ensures wide compatibility with many truck models. You receive tailored packaging solutions. This guarantees safe delivery. FANGJIE emphasizes quality and innovation. They supply reliable and efficient products. This keeps your fleet moving forward.

You now possess the knowledge to tackle clutch master cylinder issues. Proactive diagnosis and informed solutions are vital for your truck’s performance. You ensure safety on every journey. Utilize these data-backed strategies. They help you maintain your vehicle effectively. This guarantees fleet reliability and efficiency.

FAQ

How often should you check your clutch fluid?

You should check your clutch fluid level during every oil change. Also, inspect its color and clarity regularly.

Can you drive with a failing clutch master cylinder?

No, you should not drive with a failing clutch master cylinder. It compromises safety and can cause further damage to your transmission.

What is the difference between a master and slave cylinder?

The master cylinder converts pedal pressure into hydraulic force. The slave cylinder uses this force to disengage the clutch near the transmission.

Post time: Dec-05-2025